Quality as the Key to Success: Industrial Stroboscopes in Quality Control

Introduction: Quality as the Key to Success

In modern industrial production, quality determines competitiveness, efficiency, and customer satisfaction. Even the smallest defects can have significant consequences—ranging from scrap and production downtime to reputational damage or costly product recalls. For this reason, it is crucial not only to correct errors once damage has already occurred, but to identify potential sources of defects at the earliest possible stage of the production process. This is precisely where industrial stroboscopes play a vital role.

With their unique ability to visually “freeze” fast movements, stroboscopes enable real-time monitoring of production processes, early detection of defects, and targeted corrective action. As a result, the use of stroboscopes in quality control has become an indispensable element of modern manufacturing.

Why Early Error Detection Is Crucial

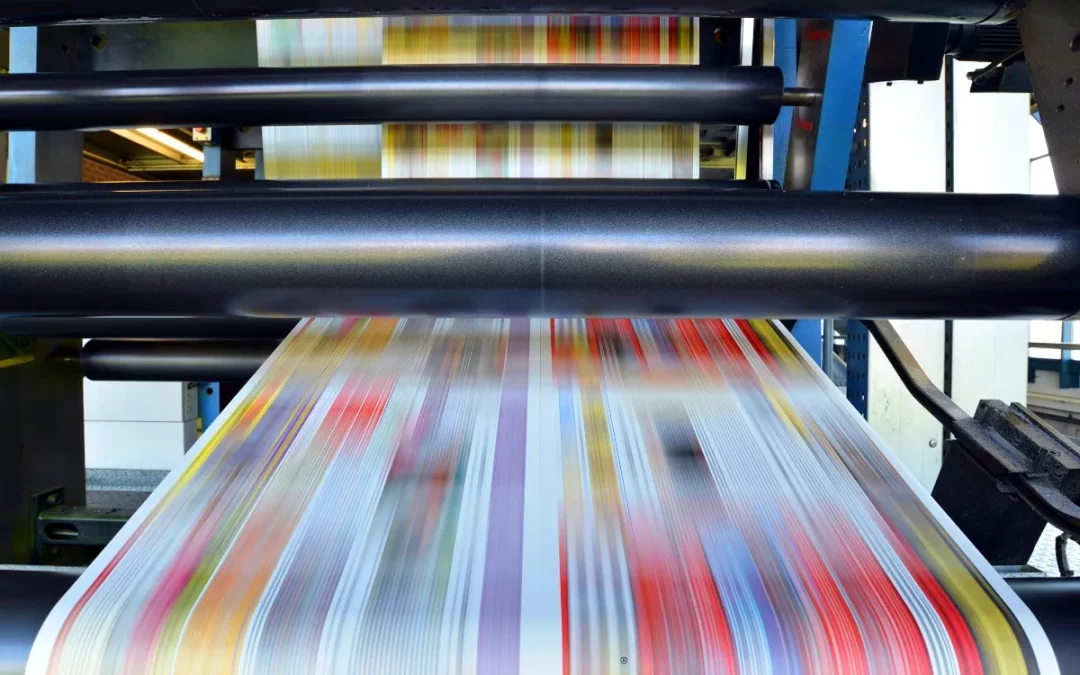

In many production environments, machines operate at very high speeds. Printing presses, textile machinery, packaging lines, and rotating drive systems all move so fast that the human eye is often unable to perceive errors or deviations.

An incorrectly tensioned thread, a printing defect, or a slightly unbalanced roller may appear insignificant at first. However, if such issues go unnoticed, they can quickly lead to large quantities of scrap, increased material and energy consumption, and costly production interruptions.

By using an industrial stroboscope, the process can be monitored during operation. Movements appear stationary under stroboscopic light, making even the smallest deviations visible. This allows errors to be detected before they cause serious damage.

How It Works: Making Motion Visible

An industrial stroboscope emits extremely bright light flashes at very short intervals. When the flash frequency is synchronized with the operating speed of a machine, the object appears stationary to the human eye.

This effect makes it possible to observe motion sequences in detail:

-

Rotational movements appear frozen

-

Vibrations can be analyzed

-

Defects such as imbalance, material cracks, or misalignment become visible

Unlike conventional measurement methods that often require direct contact with the machine or complex installation, a stroboscope offers a contactless, fast, and flexible solution.

Typical Applications in Quality Control

1. Paper and Printing Industry

In the printing industry, precision and registration accuracy are essential. Even the smallest shifts in the print image result in defective products. Stroboscopes allow continuous monitoring of paper webs and printing rollers in real time, enabling immediate correction without stopping the machine.

2. Textile and Fiber Processing

In weaving, spinning, and knitting processes, yarns must be processed under constant tension. Broken or improperly running threads lead to fabric defects. With a stroboscope, irregularities can be detected early during operation, preventing downtime and waste.

3. Packaging and Food Industry

Packaging processes require millimeter-accurate sealing, labeling, and filling. Even minimal deviations in timing or positioning can affect thousands of packages. Stroboscopes make faulty closures, incorrect label positioning, or filling errors immediately visible.

4. Machinery and Plant Engineering

Rotating components such as shafts, gears, or impellers must be precisely aligned. Imbalance not only affects product quality but also increases wear and can damage entire systems. Stroboscopes help identify such issues early, preventing costly breakdowns.

5. Automotive Industry

In the production of engines and transmissions, precise component movement is critical. Stroboscopes are used to analyze valves, pistons, and belt drives during operation, revealing irregularities that would remain hidden during standard visual inspection.

Benefits for Quality Control

The use of industrial stroboscopes offers numerous advantages for companies focused on high-quality production:

-

Early defect detection: Deviations are identified before they cause major damage

-

Continuous monitoring during operation: No machine downtime required

-

Cost reduction: Less scrap, reduced material consumption, minimal rework

-

Improved safety: Early detection of imbalance and defects protects personnel and equipment

-

Flexibility: One stroboscope can be used across various machines and processes

LED Technology as a Key Efficiency Factor

Modern industrial stroboscopes increasingly rely on LED technology. Compared to traditional xenon flash tubes, LEDs offer decisive advantages:

-

Longer light source lifetime

-

Lower energy consumption

-

Precise control of flash frequency

-

Uniform illumination of large areas

In quality control applications, where precise observation is essential, the bright and consistent illumination provided by LED stroboscopes is a critical factor.

Practical Example: Quality Control on a High-Speed Machine

A packaging company experienced recurring issues with incorrectly sealed cartons. Although the machine appeared to function correctly, defective seals occurred at irregular intervals.

Using an industrial stroboscope, the sealing process was inspected during operation. The analysis revealed that a roller was slightly out of round, causing insufficient pressure at specific intervals. Thanks to stroboscopic inspection, the issue was clearly identified and corrected.

The result: significantly reduced scrap, fewer machine stoppages, and increased customer satisfaction.

Conclusion: Stroboscopes as an Essential Tool in Quality Control

Quality control is the backbone of modern production. Detecting errors early not only reduces costs but also ensures competitiveness and customer trust. Industrial stroboscopes are a simple yet highly effective tool that reveals movements invisible to the naked eye.

Through targeted use, production processes can be optimized, machines protected, and long-term product quality ensured. In the era of Industry 4.0—where processes become faster and more complex—stroboscopes are gaining even greater importance.

Summary – Benefits of Using Stroboscopes in Quality Control

-

Error detection during operation without production downtime

-

Contactless and fast analysis of motion sequences

-

Reduction of scrap and costs through early intervention

-

Improved workplace safety through early defect detection

-

High flexibility across a wide range of industries and processes