Measuring rotational speed is a fundamental task in industrial maintenance, quality control, and diagnostics. Shafts, motors, fans, rollers, and drive systems must operate within defined speed ranges to ensure efficiency, reliability, and safety. While traditional methods often require contact sensors or machine shutdowns, industrial stroboscopes provide a powerful alternative. They allow rotational speed to be measured visually, without touching the machine and without interrupting production.

Despite their widespread use, many technicians and engineers are unsure how to measure speed correctly with a stroboscope. The method appears simple at first glance, yet it requires a clear understanding of stroboscopic principles to avoid misinterpretation. When used correctly, a stroboscope delivers accurate speed information and valuable insight into motion behavior under real operating conditions.

This article explains in detail how rotational speed is measured with a stroboscope, what principles are involved, how to interpret results correctly, and why this method is especially valuable in industrial environments.

Why Use a Stroboscope for Speed Measurement

In industrial practice, speed measurement must often be performed on running machinery. Stopping a machine for measurement may be impractical, costly, or even impossible in continuous production processes. A stroboscope makes it possible to measure speed while the machine operates normally, under load and real process conditions.

Another advantage lies in non-contact operation. There is no need to attach sensors, apply force, or modify the machine. This improves safety and flexibility, particularly when access to rotating components is limited or hazardous.

Beyond speed measurement, a stroboscope provides visual information about motion quality. This combination of measurement and inspection makes it a unique and versatile tool in industrial diagnostics.

The Basic Principle of Stroboscopic Speed Measurement

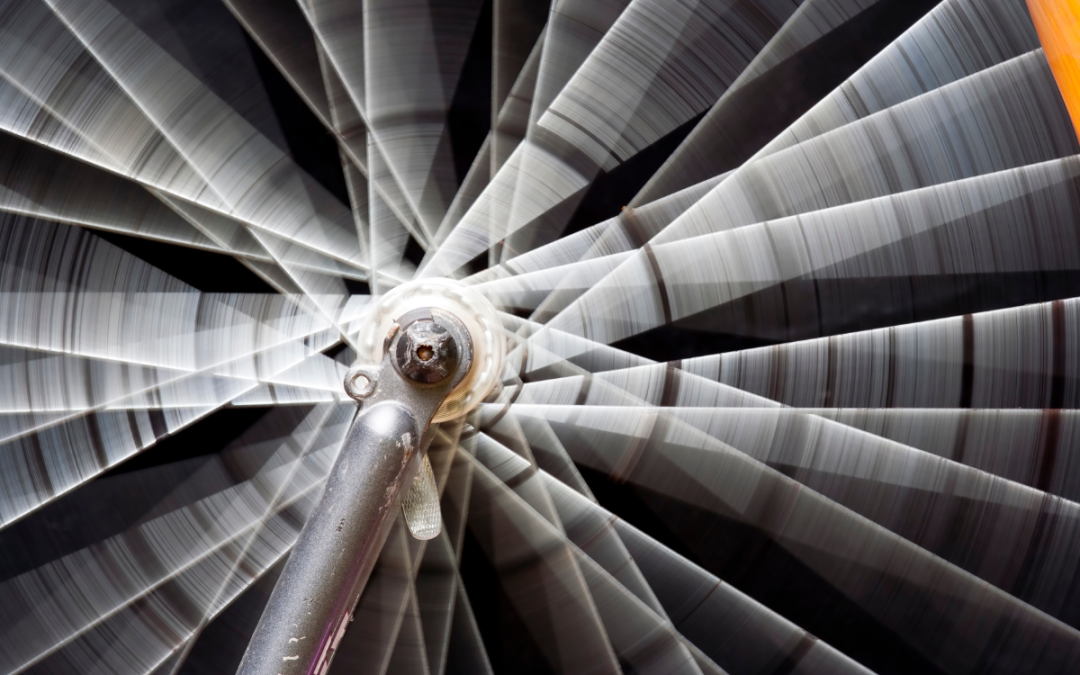

A stroboscope works by emitting short, intense flashes of light at a precisely adjustable frequency. These flashes illuminate a moving object only at specific moments in time. When the flash frequency matches the rotational speed of the object, the object appears stationary to the human eye.

For example, if a shaft rotates at 1,800 revolutions per minute and the stroboscope flashes at the same frequency, each flash illuminates the shaft at the same angular position. As a result, the shaft appears frozen in place, even though it continues to rotate at full speed.

By adjusting the flash frequency until this visual standstill is achieved, the rotational speed can be read directly from the stroboscope’s frequency display. This is the core principle behind stroboscopic speed measurement.

Preparing the Measurement Environment

Before measuring speed with a stroboscope, it is important to assess the environment and ensure safe conditions. The machine should be operating under normal conditions, with stable speed and load. Adequate visibility of the rotating component is required, but there is no need to remove protective guards unless permitted by safety regulations.

Ambient lighting should be considered. Excessive background light can reduce contrast and make it harder to observe the stroboscopic effect. In many cases, reducing ambient light improves visibility and measurement accuracy.

Equally important is maintaining a safe distance from rotating parts. Even when the component appears stationary, it is still moving at full speed. Proper training and awareness are essential to avoid accidents.

Adjusting the Stroboscope to Find the Correct Speed

The actual measurement process begins by setting the stroboscope to an approximate frequency range. If the expected speed is known, this information can be used as a starting point. If not, the frequency can be increased gradually until the motion begins to slow visually.

As the flash frequency approaches the actual rotational speed, the moving object will appear to slow down. At a certain point, it will seem to stop completely. This apparent standstill indicates that the flash frequency matches the rotational speed or a harmonic of it.

Fine adjustment is often required to achieve a stable, clear standstill. Once this is achieved, the displayed frequency represents the measured speed. In many industrial stroboscopes, this value is shown directly in revolutions per minute or flashes per minute.

Understanding Harmonics and Multiple Standstill Positions

One of the most important aspects of measuring speed with a stroboscope is understanding harmonics. A rotating object may appear stationary not only at its true rotational speed but also at fractions or multiples of that speed.

For example, a shaft rotating at 1,200 revolutions per minute may also appear stationary at 600 or 2,400 flashes per minute. This occurs because the stroboscope illuminates the object at consistent angular positions that repeat periodically.

To identify the true speed, experienced users observe the behavior of the object while adjusting the frequency slightly above and below the apparent standstill. At the correct speed, the image remains stable. At harmonic frequencies, the object may appear to jump, multiply, or shift position.

Understanding and recognizing these effects is essential for accurate measurement and is one of the reasons proper training is important when using stroboscopes.

Measuring Speed on Different Types of Rotating Components

Stroboscopic speed measurement can be applied to a wide range of rotating components. Smooth shafts, pulleys, fans, and rollers can all be measured without additional preparation. Components with visible features, such as keyways, bolts, or markings, often make visual standstill easier to detect.

In cases where the surface is visually uniform, adding a temporary visual reference may improve clarity. However, unlike optical tachometers, stroboscopes do not require reflective tape or physical markers to function.

This flexibility makes stroboscopes particularly useful in complex machinery where access is limited or modifications are not allowed.

Measuring Speed Under Load and Real Conditions

One of the most valuable aspects of stroboscopic speed measurement is the ability to measure speed under real operating conditions. Machines behave differently under load than they do when idle. Belts may slip slightly, shafts may experience elastic deformation, and control systems may introduce small speed variations.

By measuring speed during operation, these effects become visible. Subtle fluctuations that would be invisible to static measurement methods can be observed and evaluated. This information is crucial for diagnosing issues related to wear, misalignment, or control instability.

In this context, speed measurement becomes more than a numerical task. It becomes a diagnostic tool that reveals how the machine behaves dynamically.

Safety Considerations During Measurement

While stroboscopes improve safety by enabling non-contact measurement, they also introduce specific risks related to visual perception. The illusion of standstill can lead to dangerous assumptions if operators forget that the machine is still running.

Maintaining safe distance, following established safety procedures, and ensuring that all personnel in the area understand the nature of stroboscopic inspection are essential precautions. The stroboscope should never be used as a justification to bypass mechanical safety measures.

When used responsibly, stroboscopes significantly reduce the need for physical interaction with moving machinery and support safer inspection practices.

Accuracy and Limitations of Stroboscopic Measurement

Stroboscopic speed measurement is highly accurate when performed correctly. Modern industrial stroboscopes offer precise frequency control and stable light output, ensuring reliable results.

However, accuracy depends on correct interpretation. Harmonic effects, unstable machine speed, or poor visibility can affect results. In critical applications, measurements may be verified using additional methods or reference values.

Understanding the limitations of the method ensures realistic expectations and reliable application in industrial practice.

Integrating Stroboscopic Speed Measurement into Maintenance Practice

In many facilities, stroboscopic speed measurement is part of routine maintenance and inspection. Regular measurements help establish baseline values and detect deviations over time. Trends in speed behavior can indicate emerging mechanical or control issues.

Because stroboscopes are portable and easy to use, they fit well into predictive maintenance strategies. Measurements can be performed quickly during normal operation, supporting data-driven maintenance decisions.

Over time, this approach reduces downtime, extends equipment life, and improves overall process stability.

Conclusion

Measuring rotational speed with a stroboscope is a powerful and practical method for industrial applications. By using synchronized flashes of light, stroboscopes enable accurate, non-contact speed measurement without stopping production.

When users understand the principles behind the method and interpret results correctly, stroboscopic measurement provides not only speed values but also valuable insight into machine behavior. This combination makes it an indispensable tool in modern maintenance, diagnostics, and process optimization.

Used correctly and safely, a stroboscope transforms speed measurement from a simple numerical task into a comprehensive inspection technique that supports reliable and efficient industrial operations.